PRODUCTS

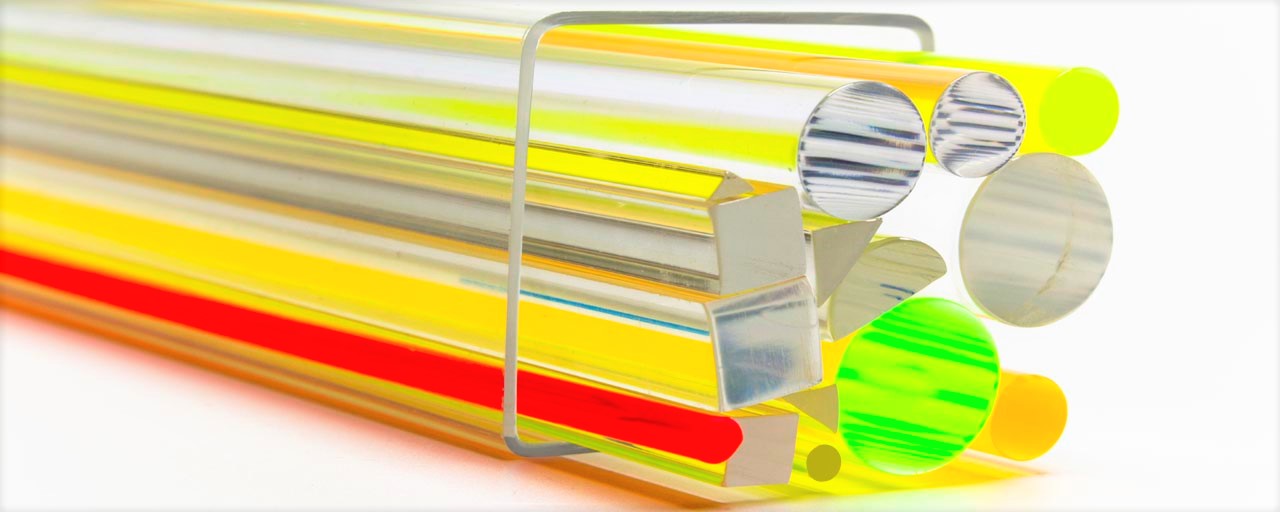

Our unique product-mix includes 30 product families such as Cast / Green PMMA / XT Acrylic and Polycarbonate Tubes, Rods, Bars, Profiles, Blocks, Accessories and Adhesives. More than 1200 items are manufactured and stocked. We are the sole manufacturer in Europe that produces 100% recycled cast acrylic tubes.

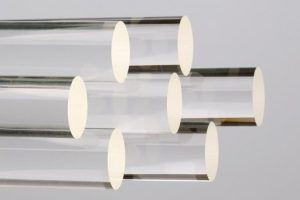

TUBES

Cast and extruded tubes made from PMMA or PC

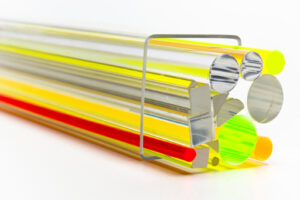

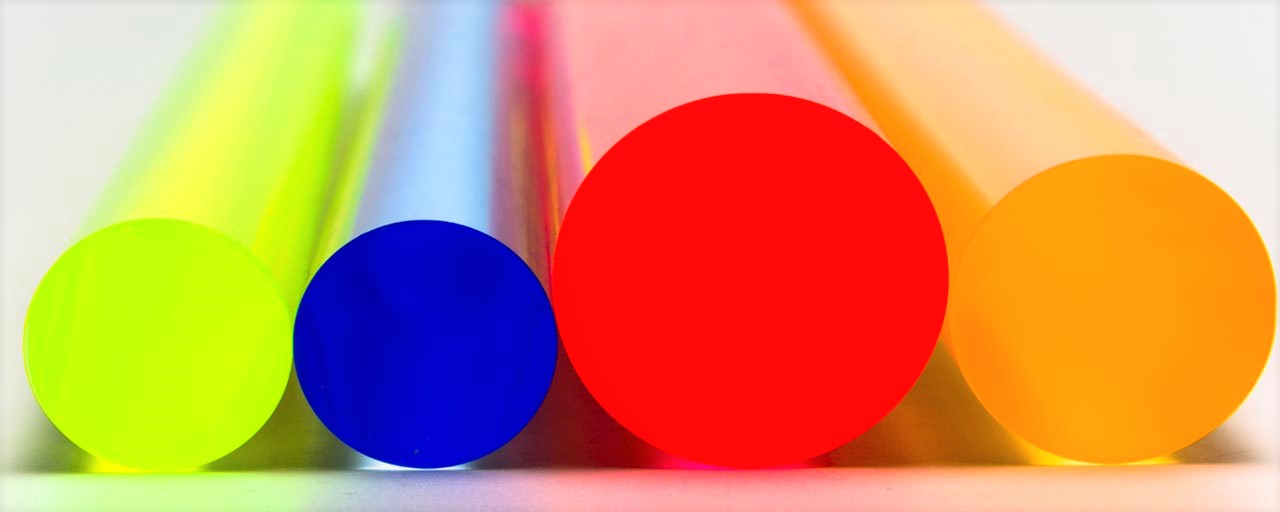

RODS

Cast and extruded PMMA rods, round and half-rounds

BARS

Cast and extruded PMMA bars, square or triangle in shape

PROFILES

We offer a wide range of PMMA and PC profiles

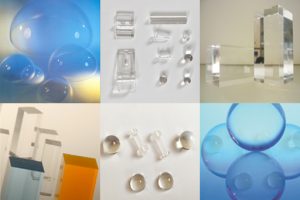

ACCESSORIES

Special PMMA Acessories

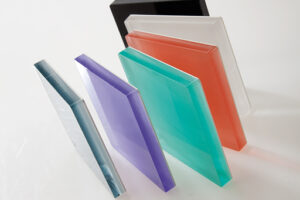

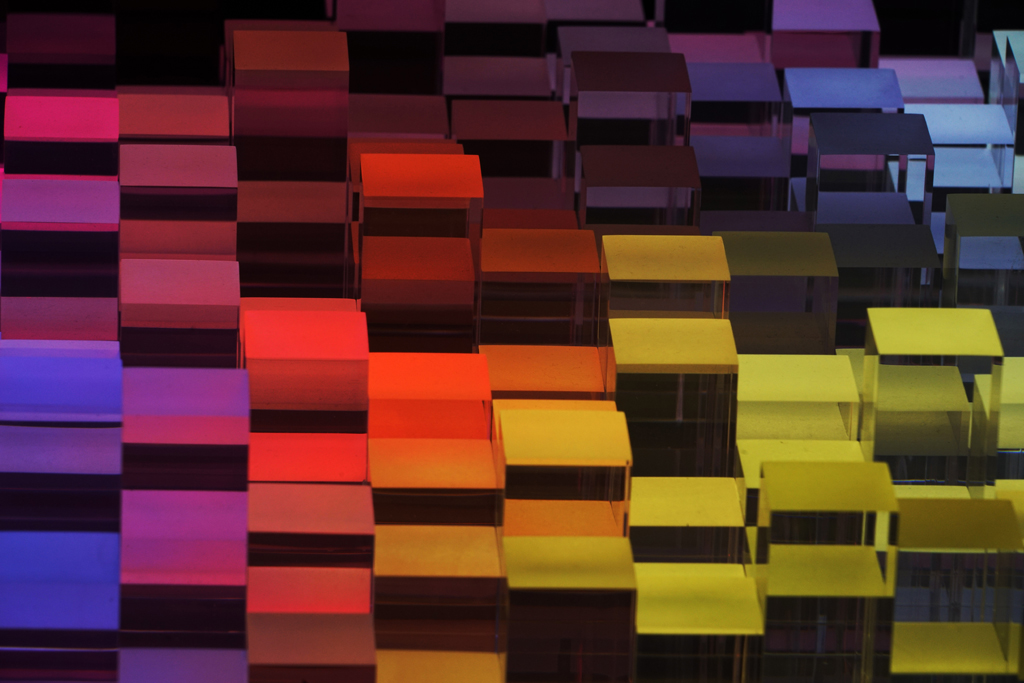

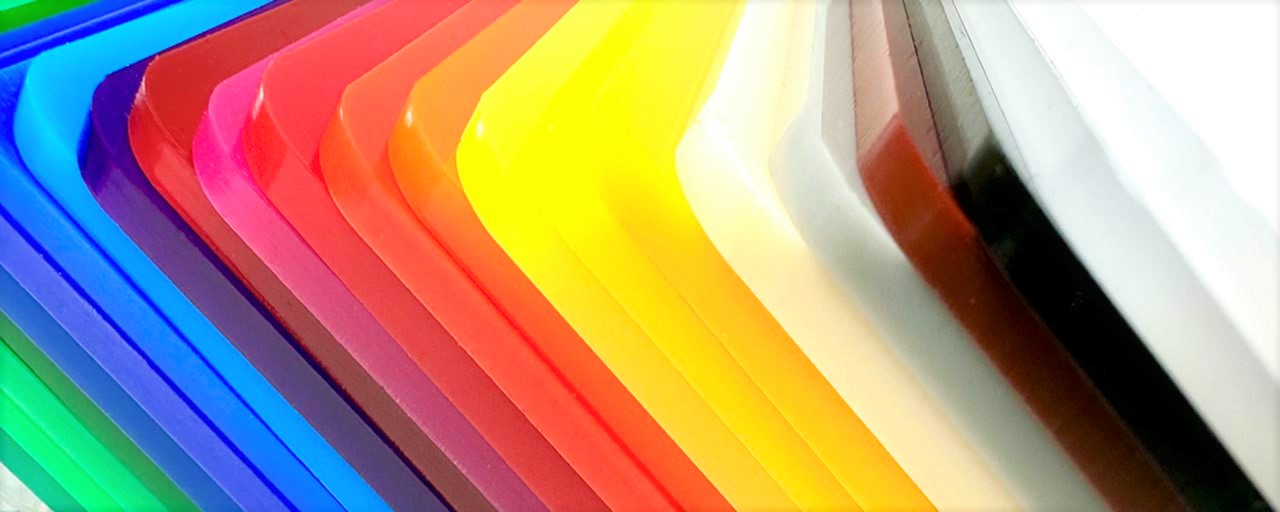

COLORED MATERIALS

Gevacril has all the colors you want

SHEETS, BLOCKS AND ADHESIVES

ENGINEERING PLASTICS

COMPANY

GEVACRIL® is a global leading manufacturer of semi-finished cast and extruded acrylic, green PMMA and polycarbonate items. GEVACRIL® cast and extruded tubes, rods, bars, profiles, accessories in PMMA and PC, recycled PMMA tubes and exports more than 75% of the production capacity to > 60 countries in the world. GEVACRIL® grants following added values: An unbeatable quality/price performance; an extremely flexible logistic system without minimal quantities; world exclusive products like Clean-Sky® R-Cast Tubes and Cast Continued® Tubes (rapid cast); product synergies which allow huge administrative and logistic savings.

MANAGEMENT PHILOSOPHY

Everyone who has ever been in contact with our team will confirm that we are working hard, we are loyal and honest, and we are devoted to deliver the highest quality product combined with outstanding consulting and service. Our aim is to offer the best added value to our commercial partners. The result is a high-quality standard, innovative products, fast and reliable service and all that at a competitive price. Another fundamental issue for our management is to respect the Earth’s environment in return for the benefit of economic development. Another key theme of our management is respect for the environment and sustainable development: GEVACRIL® was the first company in the world to produce 100% recycled cast acrylic tubes, and since 2023 has installed a photovoltaic plant for an almost carbon-neutral production of these products and the extruded tubes range. In addition: GEVACRIL® semi-finished products have excellent resistance to weathering and ageing and are therefore intended for the manufacture of long-life applications (LLC); at the end of their useful life cycle, they can be entirely used for chemical or mechanical recycling. Moreover: GEVACRIL® collects and transmits 100% of PMMA and PC production scrap to third-party companies for its complete recycling.

PRODUCTION METHODS

GEVACRIL® guarantees the highest quality across the entire production range. Every single item is individually checked and classified according to the strict criteria of our QUALITY DESCRIPTION SYSTEM (QDS) before its quality is approved.

GEVACRIL® XT : Extruded tubes and bars are polymerised semi-finished products. They are produced by extrusion: a high quality compound is melted into a dense polymer which is then extruded by a gauge into the desired shape. Brilliance and transparency are their most important characteristics along with good weathering and ageing resistance.

GEVACRIL® R-CAST (green-PMMA) : Thanks to the investment in a new polymerisation plant, Gevacril® is able to produce a 100% recycled acrylic resin and to offer a range of 120 cast recycled tubes up to OD610mm at the same quality level of cast tubes.

GEVACRIL® CAST : Cast tubes and bars are produced by casting in one piece and individually polished. Cast products have excellent optical and technical characteristics and are more resistant to stress, weathering and chemicals that could attack the xt version.

GEVACRIL® XT : Extruded tubes and bars are polymerised semi-finished products. They are produced by extrusion: a high quality compound is melted into a dense polymer which is then extruded by a gauge into the desired shape. Brilliance and transparency are their most important characteristics along with good weathering and ageing resistance.

GEVACRIL® R-CAST (green-PMMA) : Thanks to the investment in a new polymerisation plant, Gevacril® is able to produce a 100% recycled acrylic resin and to offer a range of 120 cast recycled tubes up to OD610mm at the same quality level of cast tubes.

GEVACRIL® CAST : Cast tubes and bars are produced by casting in one piece and individually polished. Cast products have excellent optical and technical characteristics and are more resistant to stress, weathering and chemicals that could attack the xt version.

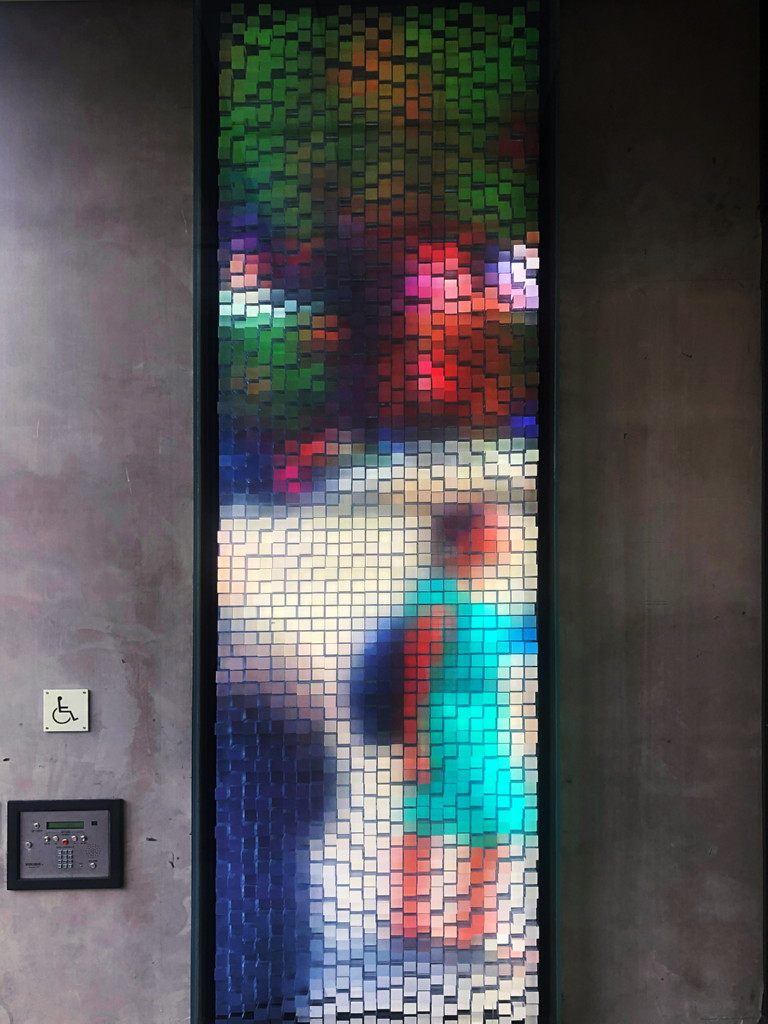

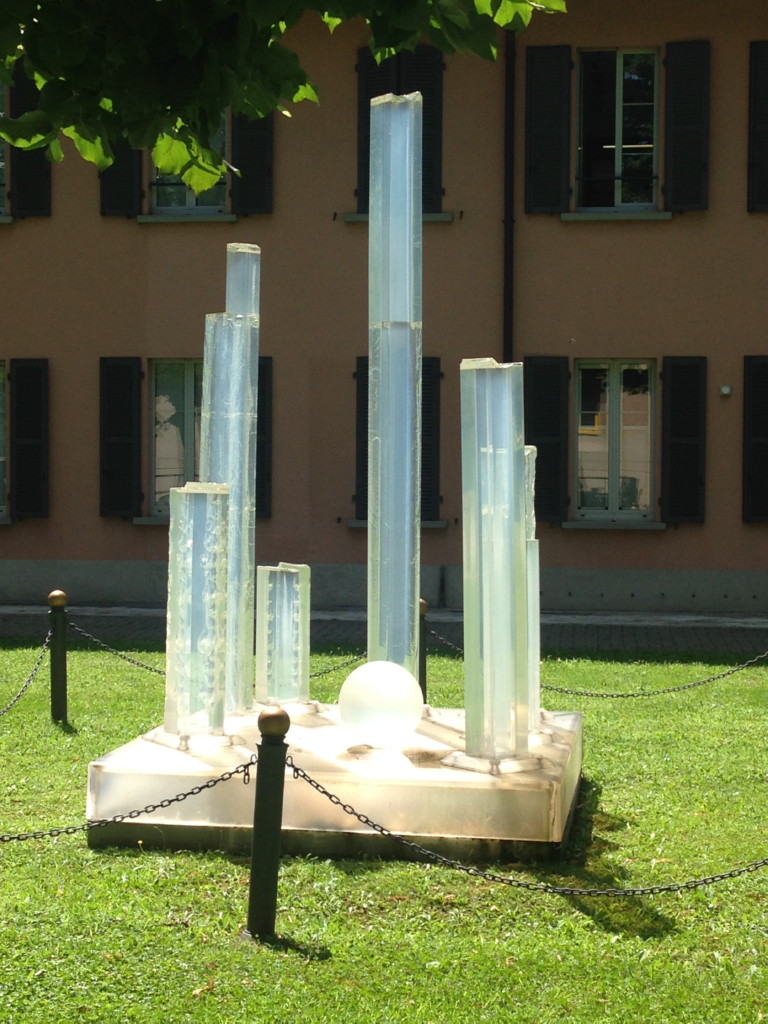

FIELDS OF APPLICATION

- exhibitions & show room decoration

- signs/displays

- housing for controlling and electronic components

- clear fluid movement, filter housings

- architectural applications (interior decoration, hand-rails, balconies, art projects, museum applications; design objects)

- furnishings

- jewelry displays

- indoor/outdoor lighting

- industrial photocopy machines (industrial scanners, photocopy machines)

.

- TV studios (set decoration, furnishings, general decorative purposes)

- automotive Sign & Display

- aerospace

- others (water filters, oil boxes, food canisters; food displays)

- indoor/outdoor buildings

- medical applications

- aquariums

To see the possibility of applications please visit our gallery