STANDARDS

DIN (German Institute for Standardisation) and ASTM (American Society for Testing and Materials) are the most internationally renowned standardisation institutes. They have long experience in the field of plastic products and perform tests based on a set of standard regulations that all products must comply with in order to achieve good market quality.

We know that our products fully comply with the standard regulations set by these two institutes, however, in order to show you the manufacturing process that leads to our excellent quality, we have decided to provide you with all the necessary information. The conclusion of this process is the implementation of our Quality System (QDS) for all Gevacril® products. This is complemented by dozens of certifications and approvals, as well as a document certifying our commitment to a sustainable economy.

Quality Description System (QDS)

Besides our semi-finished products in PMMA complies with the appropriate FOOD REGULATION, COMMISSION DIRECTIVE 90/128/EEC, and FDA REGULATION 21 CFR § 177.1010 and are manufactured according to the plastic supplier’s specifications.

Approvals & Certificates

The quality of gevacril products is guaranteed by dozens of approvals and certificates that we can supply on request:

Antislavery & Human Trafficking

Animal or Human derived materials Statement

Certificate of Conformity

Certificate of Origin

CLP Regulation

Conflict Mineral Sources Statement (US Dodd-Frank Act)

DOT (di organic tin compounds) – Statement

Food approval – FDA – NSF

Long Term Declaration

Nano Particles Statement

Persistent Organic Pollutants Statement

REACH with SVHC Statement

RoHS III directive

PBT Statement & TSCA Declaration

Asbestos/Dioxins; Bisphenol; Cobalt Statements

Heavy Metal Statement / Conflict Minerals

POP Regulation Statement

PFAS Statement

Phthalate Statement

TSE / BSE Statement

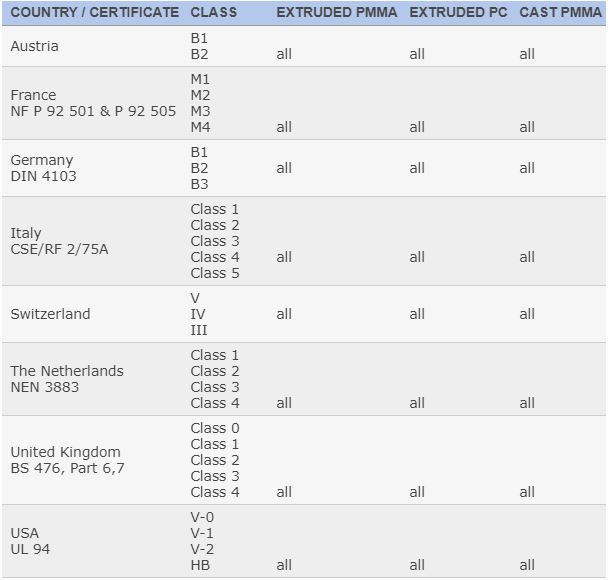

Last but not least: The following table provides an overview of the fire classification for fire prevention purposes:

Recycling & Environmental Aspects

Semi-finished acrylics from Gevacril Acrylics are used to create high-quality, long-life articles (Long Life Cycle). They are therefore environmentally friendly and are not dispersed into the environment, but mechanically or chemically recycled and 100% reused.

In 2020, GEVACRIL® introduced to the market Clean-Sky® tubes, acrylic tubes made from 100% recycled MMA. After years of research and development, investment in a new polymerisation station, Gevacril® – the first company in the world to offer this type of product – is able to produce a 100% recycled methacrylate resin and offer a product range qualitatively identical to semi-finished products made from ‘virgin’ resin.

In 2023, Gevacril Acrylics invested in a photovoltaic plant for the production of approx. 200,000 KWh/year of renewable energy. The start-up of this plant will enable an almost carbon-neutral production of the Green PMMA products and for the extrusion lines of pmma pipes and rods.

The United Nations in their dossier published in 1987 introduced the concept of “sustainable development,” development that meets the needs of the present without compromising the ability of future generations to meet their own needs. Gevacril Acrylics’ business philosophy is based on professionalism, quality and reliability, but also on a sustainable economy with zero waste of resources and minimal environmental impact.